Top Reasons to Choose Anodized Look Aluminium Over Traditional Anodizing

The Smart Metal Choice: Why Anodised Look Aluminium Outshines Traditional Anodised Aluminium

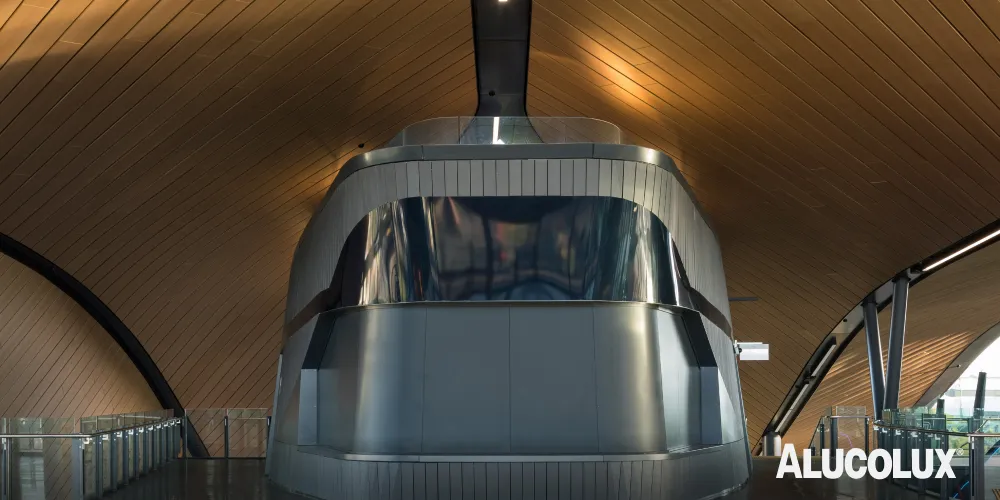

Project: Telepark | Architect: Façade Consultant – Arup Singapore, Architect – Chansez Pte. Ltd. | Fabricator/Installer: Evergreen Engineering & Construction Pte. Ltd. | Colour: Anodized Look C31/A001, C34/A004, Grey Metallic 502 | Completed year: 2023

Aluminium has long been the go-to material for modern architecture—sleek, strong, and adaptable. Among its many finishes, anodised aluminium has earned a reputation for bringing durability and elegance together. But in today’s design and construction landscape, it’s not just about how a material looks—it’s about how it performs in the real world.

Welcome to the future of facade materials: ALUCOLUX® anodised-look aluminium sheets. They offer everything designers love about anodising, with none of the limitations.

First, What Is Anodised Aluminium?

Let’s start with the basics: what is anodised aluminium?

Anodising is an electrochemical process that turns the outer layer of aluminium into a durable oxide coating. This anodic layer is not applied on top like paint—it becomes part of the metal itself. The result is a corrosion-resistant surface with a unique metallic texture and a soft, refined sheen.

For decades, anodised aluminium sheet has been used in building envelopes, facades, and interiors for its understated sophistication and industrial-grade resilience. However, traditional anodising has its challenges: inconsistent colours across batches, susceptibility to surface scratches, and fading under UV exposure over time.

Project: Telepark | Architect: Façade Consultant – Arup Singapore, Architect – Chansez Pte. Ltd. | Fabricator/Installer: Evergreen Engineering & Construction Pte. Ltd. | Colour: Anodized Look C31/A001, C34/A004, Grey Metallic 502 | Completed year: 2023

The ALUCOLUX® Alternative: The Look of Anodising, Upgraded for Performance

ALUCOLUX® solves those challenges with a clever twist: it replicates the classic anodised aluminium aesthetic using a coil-coated premium PVDF paint system.

Each sheet undergoes a multi-layer, multi-bake process that delivers a finish that doesn’t just look like anodised aluminium—it performs better.

The result? A surface that’s smooth, elegant, weatherproof, UV-stable, and fire-safe—all while maintaining the rich metallic appeal architects love.

Project: 30 Madden | Architect: South Pacific Architects, Wellington | Fabricator/Installer: Symonite Panels Ltd. | Colour: Pure White, Anodic Dark Grey, Pale Oak | Completed year: 2022

Why Architects Are Choosing ALUCOLUX® Anodised-Look Panels

Flawless Colour Uniformity

Forget mismatched panels. ALUCOLUX® offers perfect consistency across large volumes—an important edge for complex projects with demanding visual standards.

Rich Anodised Aluminium Colours

Available in tones like Satin Brown, C34, C3/EV1, C32, and C31, the finish options echo the timeless palette of true anodised aluminium colours, offering warm, cool, and neutral metallics that suit any design language.

Unmatched Weather Resistance

From harsh sun to sea spray, ALUCOLUX® panels are engineered to handle extreme environments without fading, chalking, or peeling—unlike traditional anodising which can deteriorate with prolonged exposure.

High Scratch and Impact Resistance

Where anodised aluminium shows surface imperfections easily, PVDF finishes hold up better during transport, handling, and installation—making them ideal for high-traffic or high-visibility areas.

Certified Non-Combustibility

Safety comes standard. ALUCOLUX® anodised-look sheets are non-combustible with A1 classification as per EN 13015-1 test standards, making them a safer, regulation-ready choice for commercial, public, and high-rise buildings.

Project: Te Puhinui Station Interchange | Architect: Jasmax | Fabricator/Installer: Symonite | Colour: Anthracite Grey | Completed year: 2021

Head-to-Head: Traditional Anodised vs. Anodised Look

| Attribute | Anodised Aluminium | ALUCOLUX® Anodised Look |

|---|---|---|

| Colour consistency | Variable batch to batch | Uniform across all sheets |

| Surface durability | Shows scratches and blemishes easily | Higher scratch resistance, smoother surface |

| UV & weather performance | Moderate—may fade over time | Excellent fade resistance, ideal for exteriors |

| Corrosion resistance | Strong but variable based on environment | Superior resistance to pollutants and salty air |

Designed for Landmark Architecture

Whether you’re designing the clean lines of a contemporary retail flagship, the bold facade of a corporate HQ, or the refined minimalism of a luxury residential tower, ALUCOLUX® gives you both form and function.

- Exterior cladding and rainscreens

- Curtain wall infills

- Column covers and soffits

- High-end interior walls

Project: 30 Madden | Architect: South Pacific Architects, Wellington | Fabricator/Installer: Symonite Panels Ltd. | Colour: Pure White, Anodic Dark Grey, Pale Oak | Completed year: 2022

Final Verdict: Beauty That Lasts, Performance That Leads

Traditional anodised aluminium has its place—but for modern-day demands, anodised-look aluminium finished with PVDF offers a smarter, more versatile path forward.

You get the same refined aesthetic, enhanced with better colour control, greater resistance to wear and weather, and full compliance with today’s safety codes. With ALUCOLUX®, your vision isn’t compromised by technical trade-offs.

Looking for anodised aluminium that won’t fade, stays consistent, and meets the highest standards of performance?

ALUCOLUX® delivers rich anodised colours, unmatched weather resistance, and certified safety—built for modern, landmark architecture.

Contact: sales@alucobond.com.sg

Choose ALUCOLUX®—where architectural beauty meets next-generation resilience.