ALUCOLUX® is a coil-coated solid aluminium panels widely used for architectural cladding worldwide.

ALUCOLUX® features a multi-coat, multi-bake process on a continuous coil coating line using the highest grade of PVDF/FEVE paint system. This process not only ensures the colour consistency of aluminium panels but also long-term durability and renders them non-combustible.

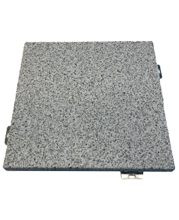

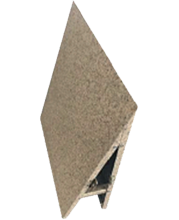

Unique patterns resembling the look & feel of a real wood and stone are also possible with ALUCOLUX®.

As an exterior and interior cladding panel, ALUCOLUX® offer versatility and durability in architectural applications. These lightweight and easy-to-install aluminium cladding panels are available in various textures and finishes making them an ideal choice for architects and consultants. Due to its ability to withstand extreme weather, solar radiation and pollution, ALUCOLUX® is mainly used as an exterior cladding panel for facades and soffits. They can also be used as interior cladding panels for accent walls, column cladding and decorative ceilings that add sophistication to any space.

Download our new ALUCOBOND® at a glance product information as PDF-file.

Download as PDF

ALUCOLUX® Product Range:

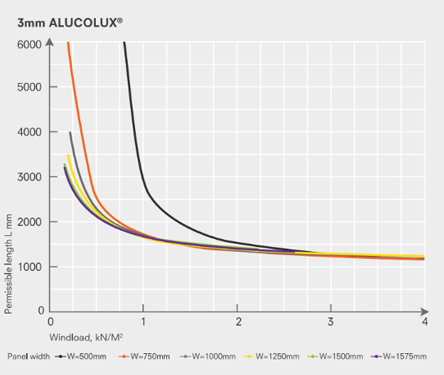

When designing and selecting cladding systems for buildings, understanding wind load and permissible panel sizes is important to ensure structural stability and longevity. Wind loads affect façade cladding, especially in high-rise buildings, based on their size, support system, and exposure conditions.

The diagram indicates the available range of panel sizes and permissible range lengths at a given panel width, depending on the wind load applied.

The diagram apply to panels supported on four sides (corners fixed). Dimensional values for other systems are available on request.

The LEED program has gained much recognition over the past several years and is now the premier sustainability design tool in the building industry. LEED focuses on constructing buildings that have minimal impact on the environment during construction and occupation and acknowledges using recycled materials is an essential part of reducing environmental deterioration.

| Material | Thickness (mm) | Weight (kg/m2) | Recycled% Pre-Consumer |

Recycled% Post Consumer |

LEED Contribution (1.0 x Post+ 0.5 x Pre) |

| ALUCOLUX® | 3 | 8.1 | 20% | 20% | 30% |

Traditionally, the solid aluminium panels used for facade cladding are manufactured using the post-painting system, where mill-finished aluminium is first fabricated and then put through a batch-coating process with a spray or powder coating method. The batch coating is done under a less controlled environment compared to the highly industrial coil-coating process.

Batch-coating of aluminium cladding panels leads to an inconsistent thickness of the paint layer across the surface, resulting in colour inconsistencies. These do not qualify as non-combustible due to the thick paint layer on the panel surface. Such aluminium wall panels are usually classified as A2 and not A1, as per the EN 13501-1 test standard. They also face limitations in terms of panel sizes, the variety of colours and surface finishes, thereby limiting designers’ choices. Moreover, there are 2 to 3 different vendors involved in getting the final product ready, resulting in a split accountability towards quality.

On the other hand, pre-coated aluminium panels have become a popular choice among architects and interior designers for interior, exterior and facade cladding due to several benefits they offer. The robust performance and modern aesthetic of aluminium wall cladding is widely used in commercial, residential and industrial buildings, offering excellent fire safety and durability, making it suitable for offices, factories, shopping malls and educational institutions.

We provide Aluminium panels in Australia, New Zealand, South Korea, Thailand, Singapore and worldwide. We proudly supply premium aluminium panels to projects worldwide, enhancing both beauty and functionality.

These PVDF/FEVE coated aluminium panels offer exceptional weather resistance ensuring long-term durability and performance. The high quality PVDF/FEVE coating is applied through a continuous industrial-grade coil-coating process conforming to stringent AAMA (American Architectural Manufacturer’s Association) 2605 performance specifications and ECCA (European Coil Coating Association) guidelines.

The alloy and temper used in the manufacturing of ALUCOLUX® is specifically chosen to ensure that the finished product has perfect flatness.

A non-combustible solid aluminium panel that has passed a larger system test BS 8414-1 and is classified as A1 as per EN 13501-1 test standard. This enables architects to offer non-combustible cladding solutions that could meet the most stringent fire safety requirements.

ALUCOLUX® is a solid and rigid aluminum panel, yet highly formable.

ALUCOLUX® wall cladding panels are available in a diverse range of metallic, solid and vibrant colours. Additionally, these pre-coated coloured aluminium sheets offer unique finishes such as embossed stone and wood look, further enhancing the aesthetic appeal and design versatility of any architectural project.

You get support from 3A Composites team in recommendation and designing of appropriate fixing systems or any other necessary assistance.

ALUCOLUX® is 100% recyclable material.

ALUCOLUX® comes with a 15-year warranty.

Black 326

Black 326 Anthrazit grey 105

Anthrazit grey 105 Fashion grey 460

Fashion grey 460 Light grey 104

Light grey 104 Biege 103

Biege 103 Cream 102

Cream 102 Pure White 10 100

Pure White 10 100 White 16 101

White 16 101×

.

Dark grey metallic 505

Dark grey metallic 505 Smoke silver metallic 501

Smoke silver metallic 501 Silver metallic 500

Silver metallic 500 Champagne metallic 503

Champagne metallic 503 Grey metallic 502

Grey metallic 502 Grey blue metallic 603

Grey blue metallic 603 Sunrise silver metallic 600

Sunrise silver metallic 600  Brilliant metallic 602

Brilliant metallic 602 Bronze metallic 504

Bronze metallic 504 Daytona gold 8703

Daytona gold 8703 Nevada copper 8705

Nevada copper 8705 Jade green metallic 9329

Jade green metallic 9329  Classic bronze metallic 9604

Classic bronze metallic 9604  Gold metallic 601

Gold metallic 601  Copper metallic 8704

Copper metallic 8704  Seafoam green metallic 604

Seafoam green metallic 604 ×

Satin Brown

Satin Brown C34

C34 C3/EVI

C3/EVI C32

C32 C31

C31×

Sakura 917

Sakura 917 Galaxy blue 918

Galaxy blue 918 White gold 919

White gold 919 Desert gold 921

Desert gold 921 Cupral 913

Cupral 913×

A2001

A2001  A2002

A2002 A2003

A2003 A2004

A2004 A2005

A2005 A2006

A2006 A2007

A2007 A2008

A2008 A2009

A2009 A2010

A2010 A1001

A1001  A1002

A1002 A1003

A1003 A1004

A1004 A1005

A1005 A1006

A1006 A1007

A1007 A1008

A1008  Wood

Wood Stone

Stone Wood

Wood Stone

StoneBelow are some examples of how ALUCOLUX® can be fabricated at our plant, thereby providing savings on wastages and reducing the overall cost for the project.

| TECHNICAL PROPERTIES | STANDARDS | COIL-COATED |

|---|---|---|

| Alloy | EN 573-3 | 3003 |

| Temper | EN 515 | H24 |

| Standard Thickness* | EN 485-4 | 3mm |

| Standard Widths** | EN 485-4 | 1000mm, 1250mm, 1500mm, 1575mm |

| Standard Length | EN 485-4 | <= 6000mm |

| Panel Weight | 8.1 Kg/m^3 | |

| Tensile Strength | EN 485-2 | 145-185 Mpa |

| Modulus of Elasticity | EN 485-5 | 70,000 N/mm^2 |

| Yield strength Rp0.2 | EN 485-2 | >= 115Mpa |

| Elongation | EN 485-2 | A50 ≥ 6% |

| Linear Expansion | EN 1999 1-1 | 2.4 mm/m at 100° C temperature difference |

| Surface | PVDF/FEVE | |

| Gloss | EN 13523-2 | 25~40% |

| Coating Thickness*** | 28-45 microns | |

| Fire Classification | EN 13501-1 AS 3837 AS 1530.3 AS 1530.1 BS 8414-1 | A1 Group 1 as per AS 5637.1 PASSED 0 (ignitibility) 0 (flame spread) 0 (heat evolved) 2 (smoke development) PASSED PASSED |