Why Solid Aluminium Sheet is the Ultimate Choice for Exterior Cladding

Power up your facade with unmatched durability, sleek aesthetics, and sustainable performance

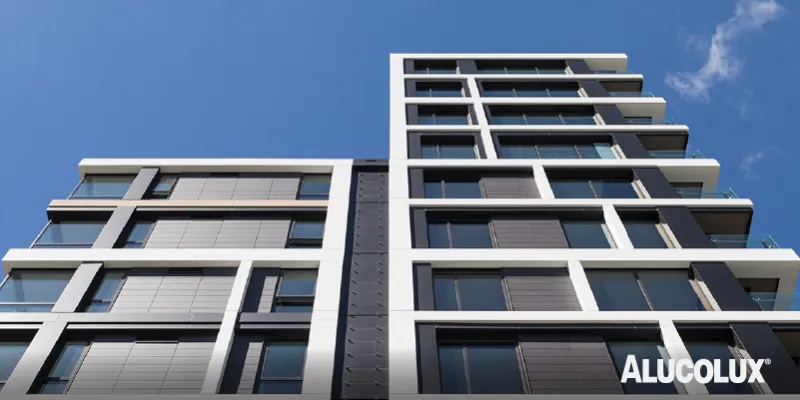

Project: Timberly Road | Architect: eclipse ARCHITECTURE | Fabricator/Installer: Symonite | Colour: Pure White | Completed year: 2021

Exterior cladding plays a pivotal role in both the aesthetics and functionality of a building. As urban architecture evolves, so do the demands on cladding materials. Architects and designers now look for materials that not only deliver on design and finish but also promise durability, low maintenance, and environmental responsibility. Among the myriad of options available today, solid aluminium sheet has emerged as one of the most effective solutions for modern exterior cladding needs.

In this blog post, we explore why aluminium sheet cladding is fast becoming the preferred cladding material across commercial, institutional, and high-end residential projects.

What is Exterior Cladding?

Project: Plaza 8 @ Changi Business Park | Architect: AC Consortium | Fabricator/Installer: Evergreen Engineering and Construction Pte. Ltd. | Colour: Beige 103 | Completed year: 2020

Exterior cladding refers to the protective layer attached to the outside of a building. It serves multiple purposes — from weather resistance to thermal insulation, and from enhancing building aesthetics to reducing maintenance costs. The cladding material acts as a skin that shields the internal structure while lending the building its architectural personality.

Over the years, the choice of exterior cladding panel has expanded significantly, with materials ranging from wood, stone, vinyl, and glass to metal sheets. Among these, solid aluminium sheet stands out for its balance of performance, visual appeal, and adaptability.

Benefits of Using Solid Aluminium Sheet for Exterior Cladding

1. Exceptional Durability and Weather Resistance

One of the core reasons why aluminium is highly sought-after for exterior cladding is its outstanding durability. Solid aluminium sheets are non-corrosive, meaning they do not rust or corrode when exposed to rain, sunlight, or pollution. For this only architecture grade alumimium alloy 3xxx/5xxx should be used. They maintain their integrity for decades, even in coastal or industrial environments where other materials would typically fail.

Project: 30 Madden | Architect: South Pacific Architects, Wellington | Fabricator/Installer: Symonite Panels Ltd. | Colour: Pure White, Anodic Dark Grey, Pale Oak | Completed year: 2022

2. Wide Range of Surface Finishes

Solid aluminium sheets are available in a variety of finishes, enabling architects to create facades that are both distinctive and harmonious with their surroundings. These include:

- Metallic finishes for a contemporary sheen

- Solid and Vibrant colours for the dash of elegance

- Anodised Look for satin matt finish

- Brushed aluminium for an industrial aesthetic

- Glossy and high-gloss coatings for a premium appearance

- Custom colours for brand-aligned or themed designs

Most importantly, embossed wood and stone patterns are also available in solid aluminium sheets giving a facade look and feel of the real material. For durability, manufacturing process should include a multi-coat, multi-bake system on an industrial-grade coil coating line, using high-performance PVDF or FEVE paints that comply with AAMA 2605 superior performance specifications. This ensures a consistent finish, superior weather resistance, and long-term colour stability, even in harsh climates.

3. Design Versatility and Customisation

The visual appeal of aluminium is undeniable. Whether you’re aiming for a minimalist contemporary look or a bold, high-gloss finish, aluminium sheet cladding offers immense flexibility in design. Its ability to be cut or bent into custom shapes also mean that you can achieve 3D shapes that other materials struggle to match.

Solid aluminium sheets can be laser-cut, perforated, embossed, or engraved — enabling creative freedom in architectural expression. Whether used for dramatic geometric patterns or for incorporating natural ventilation through perforated designs, aluminium sheet cladding allows for unique and functional facades.

Project: District Secretariat Gampaha | Architect: ARCHT-X Architectural Consultants | Fabricator/Installer: JC Enterprises | Colour: RAL 7048 (Custom) | Completed year: 2022

You can also choose thicknesses and panel sizes to match the scale and style of your project, whether it’s a subtle refresh or a complete exterior transformation.

4. Lightweight Yet Strong

Compared to steel, tiles, marble and stone, solid aluminium sheets are lighter in weight. This property makes transportation, handling, and installation easier and more cost-effective, without compromising on safety or structural reliability.

For multi-storey buildings, this is particularly important. A lighter cladding material reduces the load on the structure, which can translate into savings on foundation and framing costs.

5. Low Maintenance

Unlike materials like wood or steel, which require regular upkeep to avoid decay or rust, aluminium sheet cladding needs very little maintenance. A periodic wash is often enough to keep the facade looking pristine. This makes it ideal for commercial buildings and high-rise projects where regular maintenance is logistically challenging and expensive.

The surface coatings applied to aluminium panels — including PVDF/ FEVE further enhance resistance to dust, staining, and pollution.

Project: Telepark | Architect: Facade Consultant – Arup Singapore, Architect – Chansez Pte. Ltd. | Fabricator/Installer: Evergreen Engineering & Construction Pte. Ltd. | Colour: Anodized Look C31/A001, C34/A004, Grey Metallic 502 | Completed year: 2023

6. Fire Resistance and Safety

In building design, safety is paramount — especially in high-occupancy or critical-use structures. Solid aluminium sheets offer a distinct advantage with their non-combustible nature, high melting point, and the absence of toxic fumes when exposed to heat. Pre-coated aluminium cladding panels meet the highest Class A1 fire classification as per EN 13501-1 standards, while post-coated variants achieve Class A2 fire-resistant ratings

This exceptional fire performance makes aluminium sheet cladding a reliable and responsible choice for buildings where safety cannot be compromised — such as airports, hospitals, schools, and public infrastructure.

7. Sustainable and Recyclable

In an era of green building and environmental responsibility, aluminium scores high as a sustainable cladding material. It is 100% recyclable without losing any of its original properties.

Choosing aluminium sheet cladding supports LEED certification goals and aligns with the values of sustainable development, making it a responsible choice for future-ready architecture.

9. Excellent ROI in the Long Run

Although the initial investment in aluminium cladding may be slightly higher compared to some low-cost alternatives, its long lifespan, minimal maintenance, and energy efficiency make it a cost-effective solution over the building’s lifecycle.

Moreover, its premium appearance can significantly enhance the perceived value of a property, providing both aesthetic and commercial return on investment.

Applications of Aluminium Sheet Cladding in Architecture

Solid aluminium sheets are used in a wide variety of applications, including:

- Public infrastructure such as metro stations, airports and other mass transit systems

- Commercial and residential complexes

- Educational and healthcare institutions

- Stadiums and sports arenas

- Malls and multiplexes

- Industrial buildings

Whether used in full facade systems or accent panels, aluminium sheet cladding enhances the visual and functional aspects of a building.

Take away:

As the demand for high-performance, low-maintenance, and aesthetically flexible building materials grows, solid aluminium sheet proves itself as a frontrunner in the world of exterior cladding. It ticks all the right boxes — strength, beauty, safety, sustainability, and value — making it the ultimate choice for architects, developers, and building owners alike.

Whether you’re planning a new project or upgrading an existing structure, investing in aluminium sheet cladding is a decision that pays off in the long run — both visually and functionally.

Searching for the ultimate cladding solution?

Choose ALUCOLUX® solid aluminium sheets for unmatched weather resistance, strength, and sleek surface quality—engineered to outperform in every environment.

Contact: sales@alucobond.com.sg

Get in touch to explore how ALUCOLUX® elevates your cladding game.